Hydrogen H2 Supply Chain

March 18, 2021 2021-03-18 23:34Hydrogen H2 Supply Chain

Hydrogen H2 Supply Chain

Hydrogen…why?

Hydrogen is widely regarded as a promising energy carrier for decarbonizing road transport, mitigating the emission of harmful gases, and enhancing the

security of energy supply; accordingly, hydrogen economy has attracted more and more attention around the world recently.

A variety of governments have published technology roadmaps of hydrogen economy, according to which, the scientists and engineers can closely monitor the scheduled progress of hydrogen technologies.

How to Make Hydrogen Energy

There are a number of ways to make hydrogen. Around 95 per cent of the world’s hydrogen is made using fossil fuels, either by using natural gas via a steam methane reformation process or using a coal gasification method. This type of hydrogen is commonly referred to as brown hydrogen. When the carbon emissions from the hydrogen production (for example from the methane in steam methane reforming) are captured and permanently stored, this is known as blue hydrogen.

What Is a Supply Chain?

Supply chain is a network between a company and its suppliers to produce and distribute a specific product to the final buyer. This network includes different activities, people, entities, information, and resources. The supply chain also represents the steps it takes to get the product or service from its original state to the customer.

Supply chains encompass the companies and the business activities needed to design, make, deliver, and use a product or service. Businesses depend on their supply chains to provide them with what they need to survive and thrive. Every business fits into one or more supply chains and has a role to play in each of them.

Hydrogen H2 Supply Chain

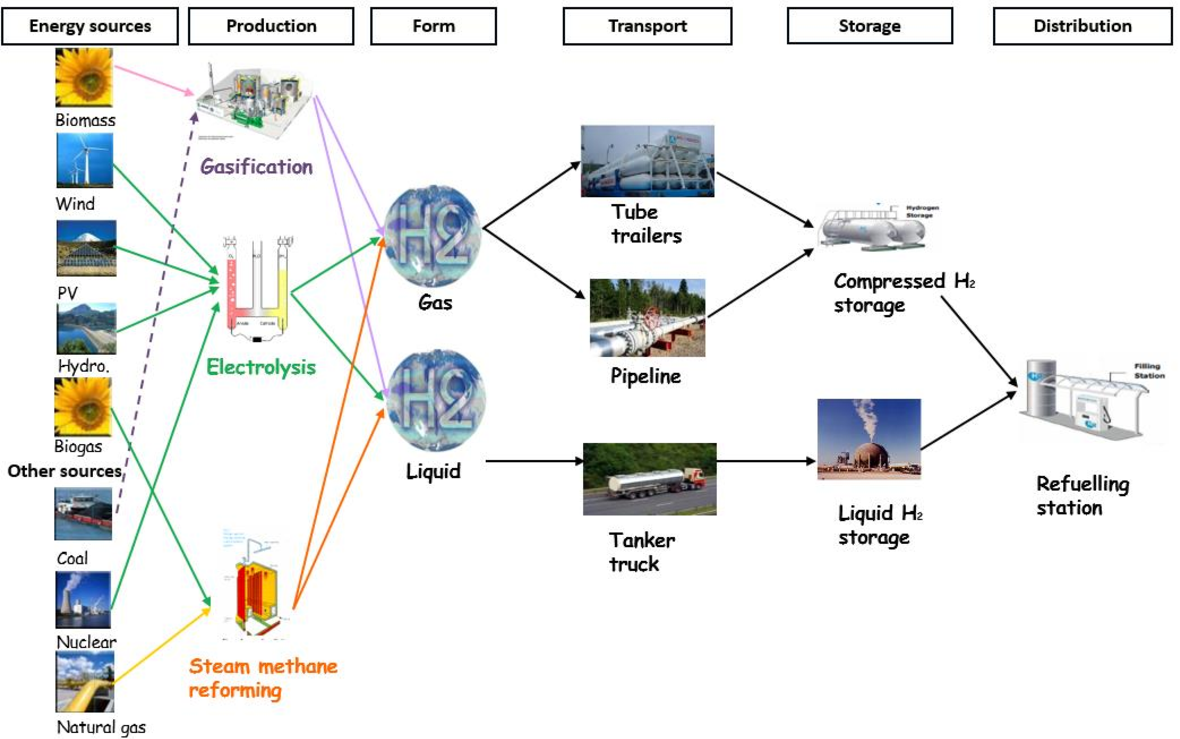

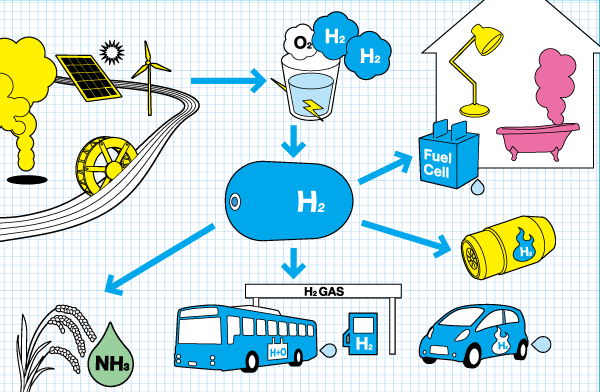

The Hydrogen H2 Supply Chain as a fuel is defined as a system of activities from suppliers to customers. These activities involve an energy source and various stages such as production, storage, transportation, and dispensation of hydrogen to refueling stations.

Unlike most other fuel infrastructures, hydrogen can be produced either centrally (similar to existing gasoline supply chains) or distributed (as small-scale units that can produce H2 close to the use point in small quantities) modes at forecourt refueling stations (with reduction on the distribution cost).

The stakeholders involve as economic, social, or institutional agents, business enterprises, and cultural groups of a specific country or region related to the hydrogen economy.

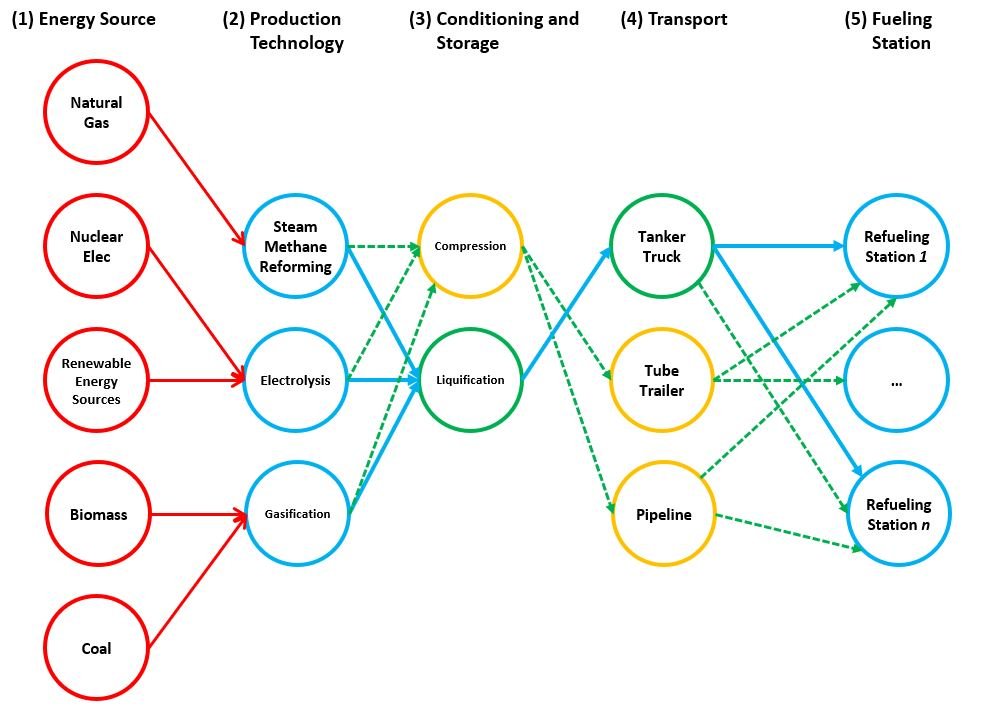

The selection of the “best” hydrogen pathway involves the comparison of various technological options in terms of multiple performance criteria, with the ultimate goal being to define a strategy whereby the infrastructure investment can be planned with confidence. Several options are presented in Figure.

In that context, some questions arise:

- Which is the environmental impact of the energy source used to produce H2?

- Which production option is more cost-effective?

- Is centralized production more cost-effective than decentralized production (small-scale production at local fueling)?

- What are the most cost-effective transportation modes and pathways to connect hydrogen demand with its supply?

- Does the well-to-wheel of the HSC result in less CO2 emission than those related to gasoline and diesel fuels?

- What is the safest configuration of the HSC and which quantitative criterion can be used to evaluate safety?

HSC modeling requires the identification of the main characteristics of its activities. A general representation of the well-known options is displayed in Figure. It must be emphasized that the degree of maturity is not the same among all the technologies.