Plant Instrumentation (1)

May 7, 2020 2020-05-20 15:15Plant Instrumentation (1)

Plant Instrumentation (1)

What is Instrumentation?

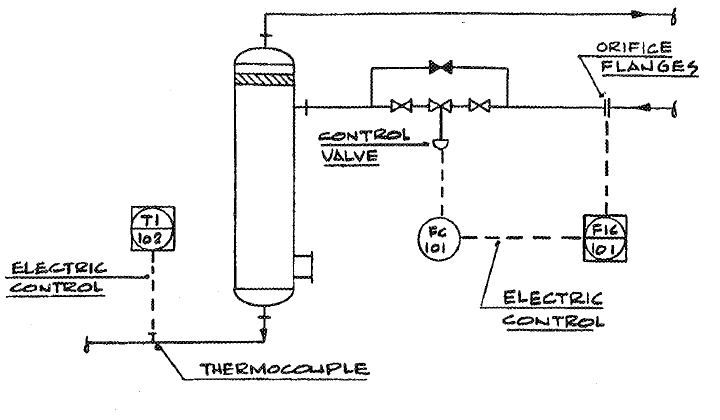

The term “instrumentation” is used to mean two things. The first is the use of measuring instruments to monitor a process (sensors). The second is the equipment used to achieve control (actuators).

Online sensors are connected to equipment and piping. It commonly include pressure, temperature

,level, flowmeters. It provides the immediate continuous measurements of process conditions . This is used to control the process. Noting that, Poor layout of instruments can have serious consequences for process stability.

Off-line sensors are often housed in enclosures on the plant, or contained in a laboratory. Sample points have to be

provided at locations which can safely provide representative samples for analysis. Control actions can be initiated by means of dedicated locally mounted controllers, but process control is more commonly achieved nowadays via either smart instruments.

It is notable that most control logic nowadays is electronically mediated, even where actuators are driven pneumatically. Field-mounted mechanical controllers are largely a thing of the past on new plants.

Get more knowledge from this books

Poor layout of instruments can have serious

consequences for process stability.

Stakeholders and Design Considerations

The owner of instrumentation work is mainly the Instrument engineer. He/she have the knowledge to select and specify all kind of instruments. Moreover, participate in relevant studies that make sure the plant will be under control.

Other stakeholders are process, equipment and piping engineers. They work together during project design phase

to exchange information and assure that plant operation/control philosophy is achieved.

While the detail of this is a matter for discussion between specialists, Plant Layout and Piping Engineers need to understand that the layout of instrumentation can affect all design considerations.

Different codes and standards such as ASME, ISA and BS are applicable for this work.

It is Really Important

A sensor in the wrong place can measure an unrepresentative part of the process stream. Signals from that sensor can be degraded by signals cabling placed too close to power cabling. An unsuitably placed control valve may have poor control characteristics.

For Value Engineers

In the context of Function Analysis System Technique FAST, here we see that instrumentation functions are:

- Measure Pressure

- Measure Temperature

- Measure Flow

- Measure Level…..etc

Functions are described using the famous two words method “Active Verb and Measurable noun”